Clean air is becoming increasingly important. Also within your environment. That is why you can use an industrial ventilator to extract dirty air, blow in fresh air, remove chemicals and cool processes. Such an industrial fan can therefore be used anywhere. Naturally, they are more robust, which means that you can continue to use an industrial ventilator for quite some time.

We like to keep it simple. Therefore, a simple explanation: An industrial fan sucks air in on the suction side, increases the pressure on the gas, and then, at the higher pressure, squeezes the air out on the discharge side. It is a rotating machine in which air is set in motion.

We can supply such an industrial ventilator in various versions. Depending on your application and business circumstances, we will look for the best option. The most widely used and sold industrial ventilator is a ventilator housing with an engine seat, supported on the ground. We call this version type 4.

As we previously described, the industrial fan provides better and cleaner air. So that means you can use the fan in almost any industry. Would you like to have a chat with our professionals? You can do so by contacting us at sales@slingerlandtechniek.nl

We have a number of cases for you. Where the industrial fan is used, among other things. Do you recognize yourself or the company in this?

Dust is created in many production processes. During the processing of materials, you always have to deal with industrial fans. Like producing wooden doors. During the production of wooden doors, the raw material is processed to make a lovely front door. Sanding, sawing, milling: This goes without saying. During this process, a lot of fine and rough dust is created. Of course you want to extract this as swiftly and as clean as possible through the industrial ventilator. The dust is extracted and the air is blowed out through a filter to the outside. The industrial ventilator immediately provides clean air inside. Very pleasant for the working environment of your employees. An extra advantage no warm air is lost in during the process.

Reducing the volume of waste is done through waste incineration. Toxic components are decomposed and energy is generated. Did you know that waste burns at temperatures above 850 degrees? The steam process to generate electricity is similar to power plants. You might have guessed it during this process, the dirty air has to be extracted and released to the outside through a filter. Naturally, the air is cleaned as thoroughly as possible.

A surface treatment or surface coating is a process by which a coating is applied to a substrate. For example galvanizing, pickling and passivation, lacquering or chromium plating. You want to be able to filter and purify the fumes and fine dust that are released during this process as quickly and effectively as possible. An important aspect of a spray booth is that the air must be extracted at the right speed. This is where an industrial fan also comes in handy.

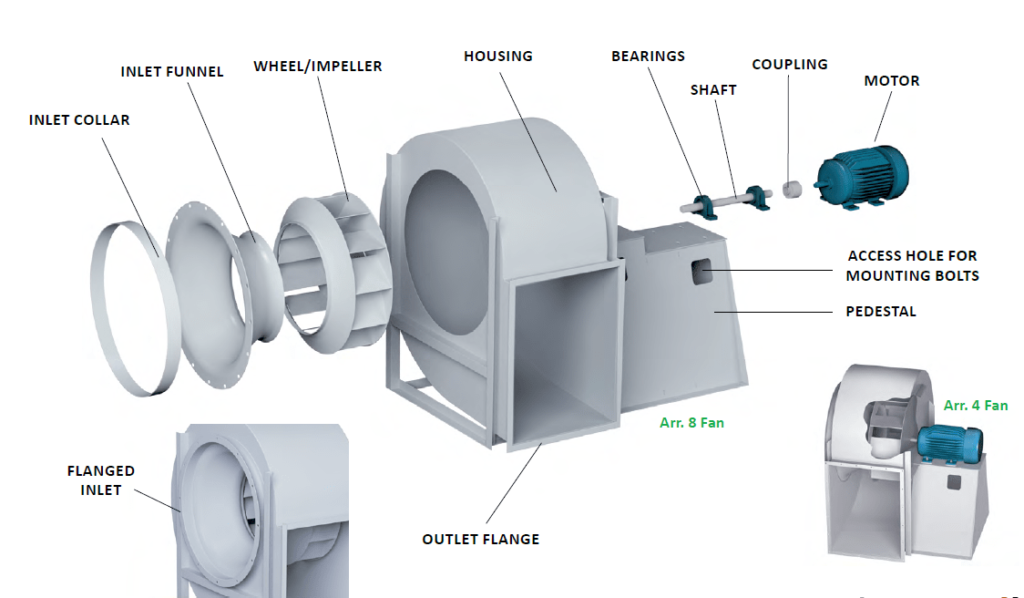

We can simply list the components of an industrial fan. But we would like to explain to you which parts you can find in the industrial fan. Of course, in particular cases, a special fan is made so that it precisely fits the customer’s needs.

Since we cited the most used and sold fan before, we’ll do it the same thing again here. Version 4 is a direct driven fan where the impeller is mounted directly on the motor shaft. A seat is provided under this motor so that the fan can be simply placed on the ground. Of course, the fan consists of an impeller that moves the air. The housing around this fan ensures that the air is sucked in via one side and can be blown out via the opposite side in the desired direction. The inlet cone ensures that the air is guided towards the impeller in a proper motion. To make it tangible see the exploded view below.

We can well imagine that you might need some help with this. We are committed to always be there for you and pledge to respond quickly to our mail. For a quick sparring session you can contact us through sales@slingerlandtechniek.nl

The choice of an industrial fan depends on a number of applications and conditions of the working environment. Obviously, heavier fans are used in heavy industries. A number of points to watch out for:

Once you have gone through these points, it is essential to think carefully about the brand of the motor. The motor is the heart of the industrial fan. When the motor is not running, the fan will also stop running. Therefore, ensure that you choose a fan with a long lifespan.

There is a lot involved in picking the right fan. We understand like no other that it is difficult to find the right application. Would you like customized advice for your work environment? Then call us at 033 – 465 13 92 or e-mail us at sales@slingerlandtechniek.nl This way we can take a look at your company situation and offer you a tailor-made solution.

A fan spends a fair number of hours running. And is often expelling polluted air or dust particles: maintenance is important to prolong the life of your fan. You can simply start by checking the grilles of the protection devices. If necessary, replace these grilles in time before malfunctions or heavy wear and tears have a chance.

Obviously, you want to prevent damage from occurring in your industrial fan. More importantly: the health of your colleagues. Two essential components that primarily require maintenance are the impeller and the fan. The impeller ensures the correct direction of the air: extracting and blowing. Clean the inside of the industrial fan regularly. It is important to keep the motor and bearings of the impeller clean. Do you want to be assured of a properly functioning fan? Check the points above once a quarter for the best results.