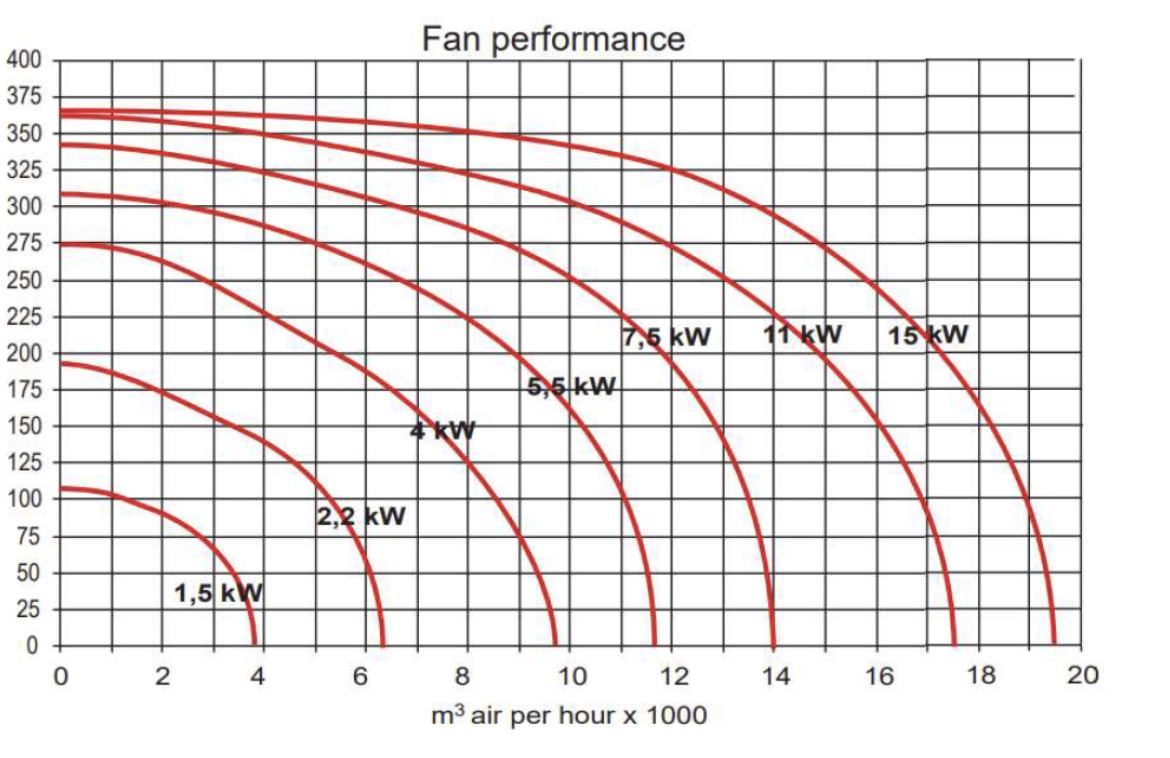

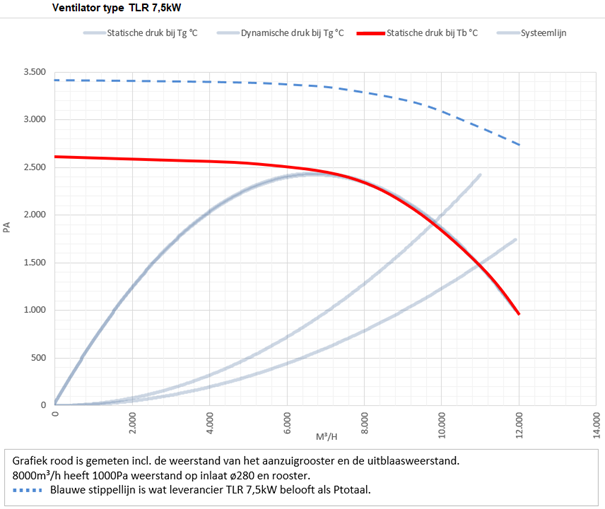

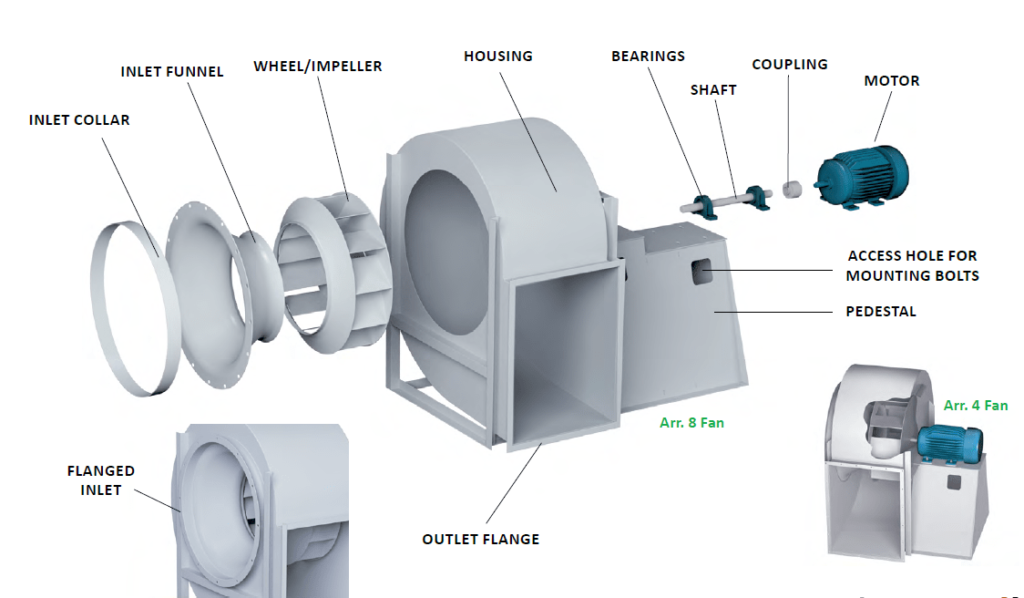

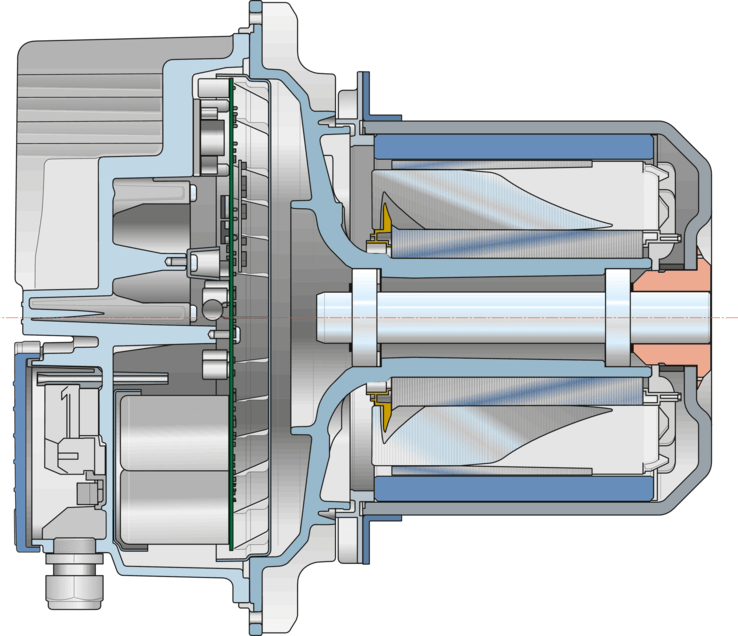

Some basic mechanical laws come into play in the operation of a fan. But what happens when you change the speed by controlling it back with an AC drive? Understanding fan operation and speed control will help you better manage your fan and optimize its performance.

When the fan speed changes, the air volume also changes. This also affects the pressure (∆ PStat) that the fan can handle, which is directly proportional to the air volume. This means that the pressure increases or decreases quadratically with speed.

In addition, the fan’s power input changes to the 3ᵉ power output as the speed changes. This can have important implications for energy consumption and efficiency.