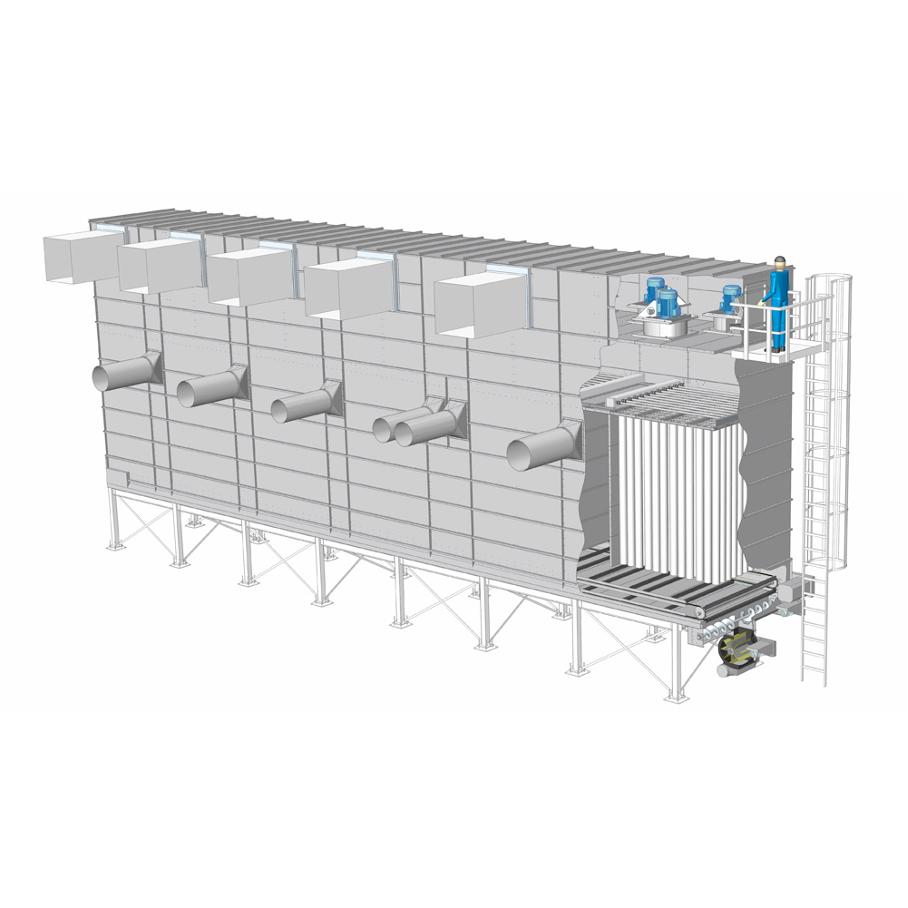

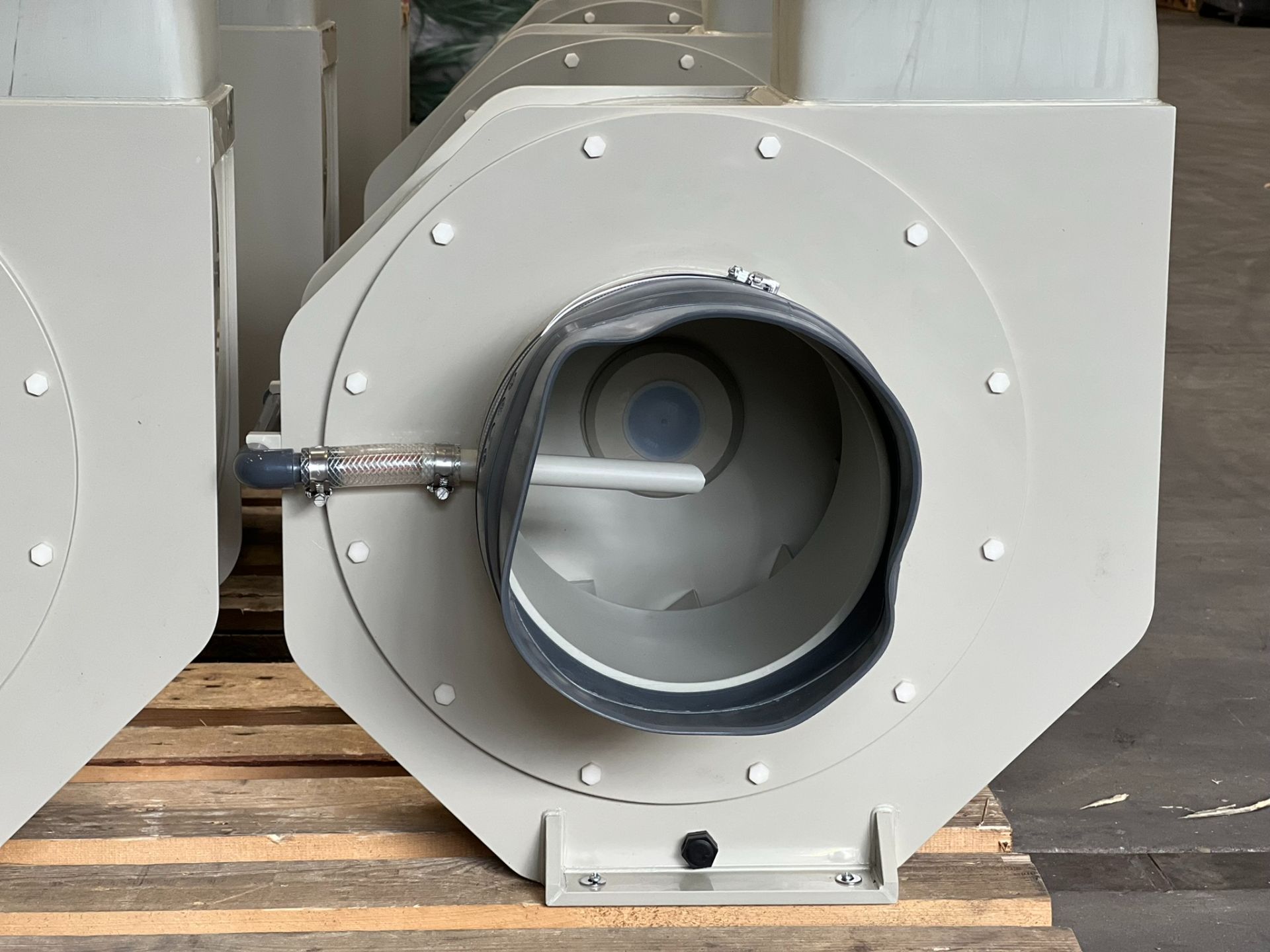

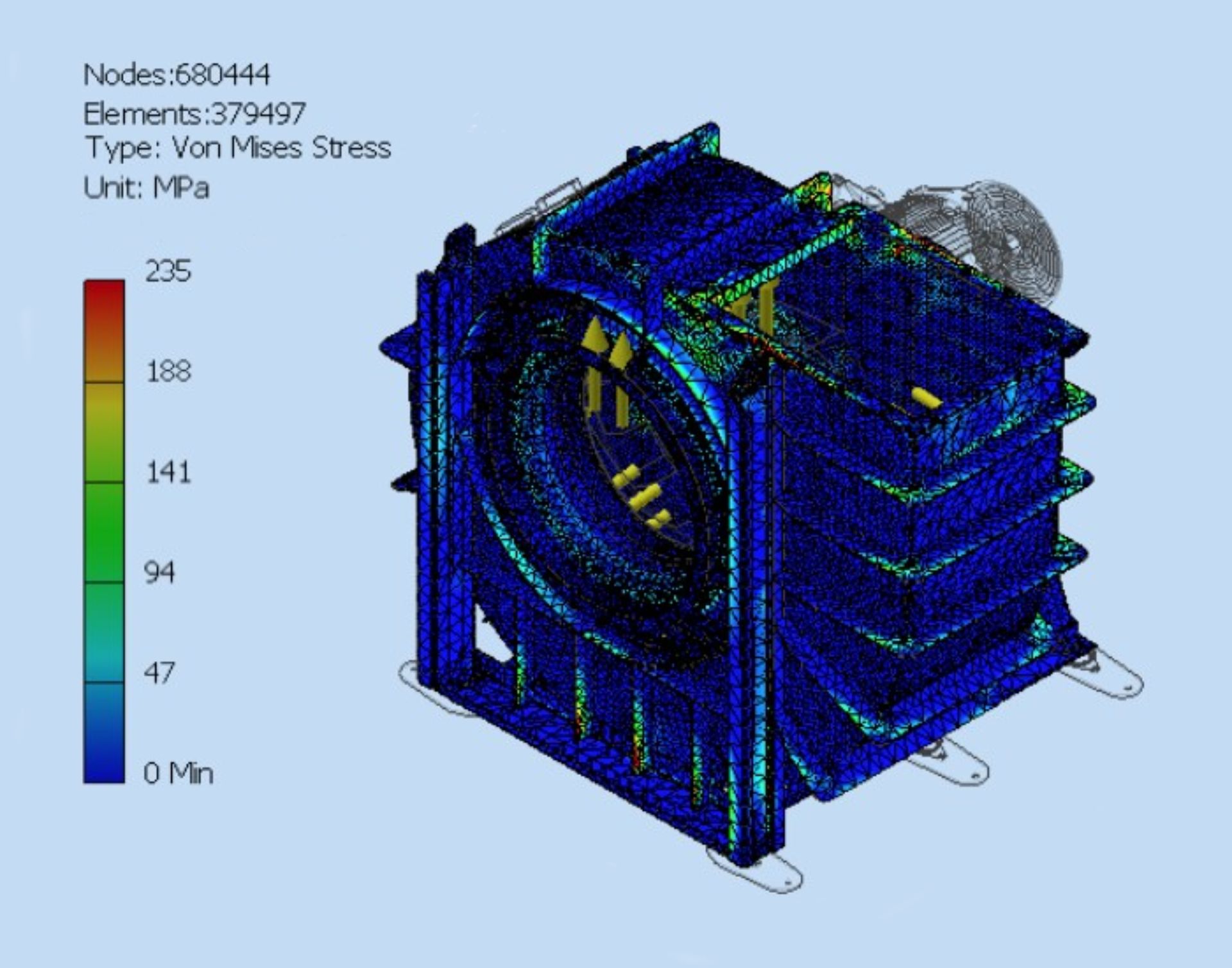

We were recently asked by a customer if we could provide a solution for an installation to extract process air from a chemical air scrubber into a drying process. From the biogas plant, they were extracting the hot air and later wanted to use it to dry liquid digestate fermented out on a belt dryer into a dry organic manure pellet.