Dust nuisance is a common problem in industry. In recent years, air quality has been the subject of more and more discussion. Since the outbreak of the coronavirus, a great deal of attention has been paid to particulate matter. In addition, we also hear a lot of noise about CO2 in the ambient air due to environmental issues. However, dust problems have been occurring in production environments for much longer.

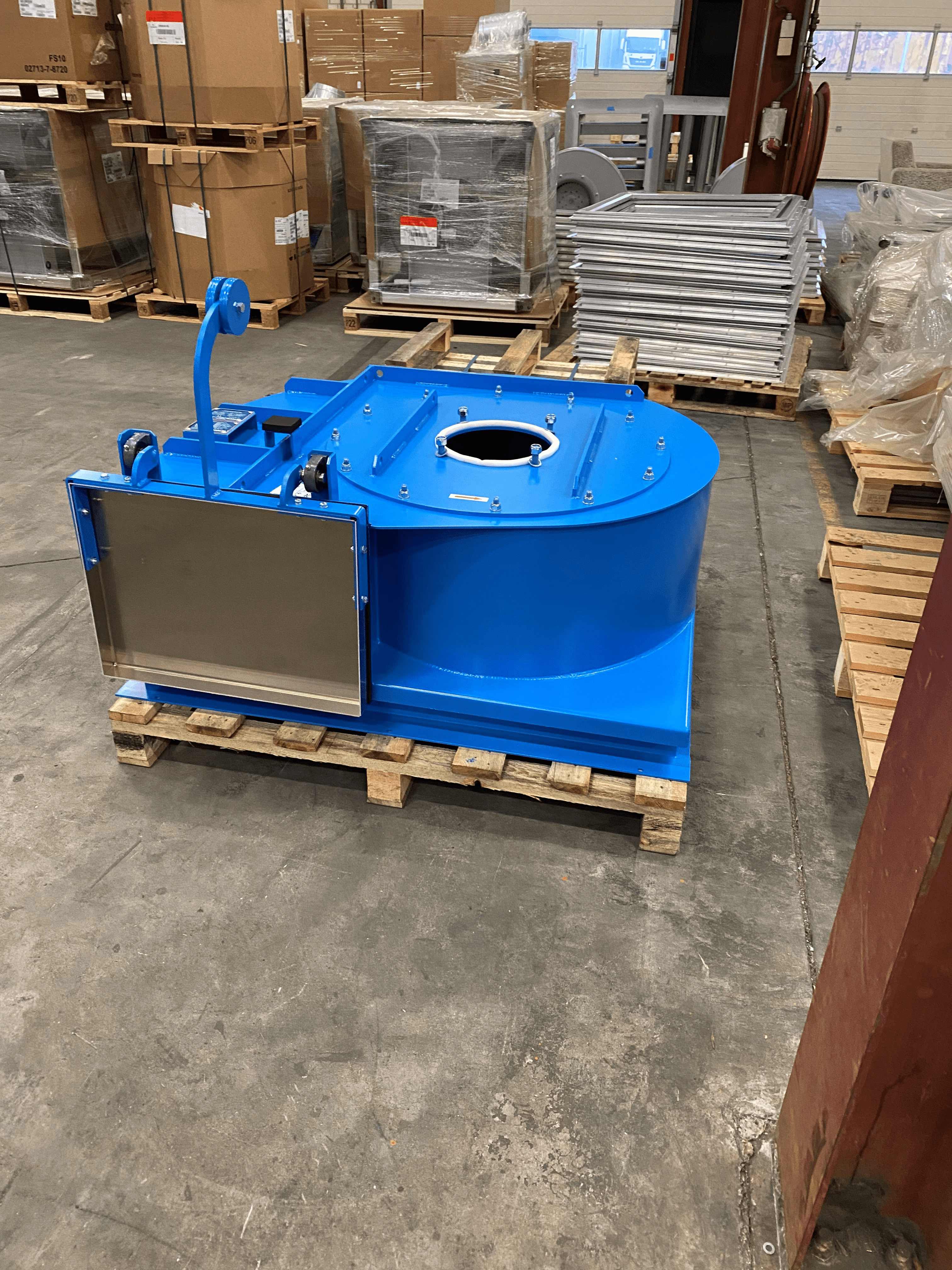

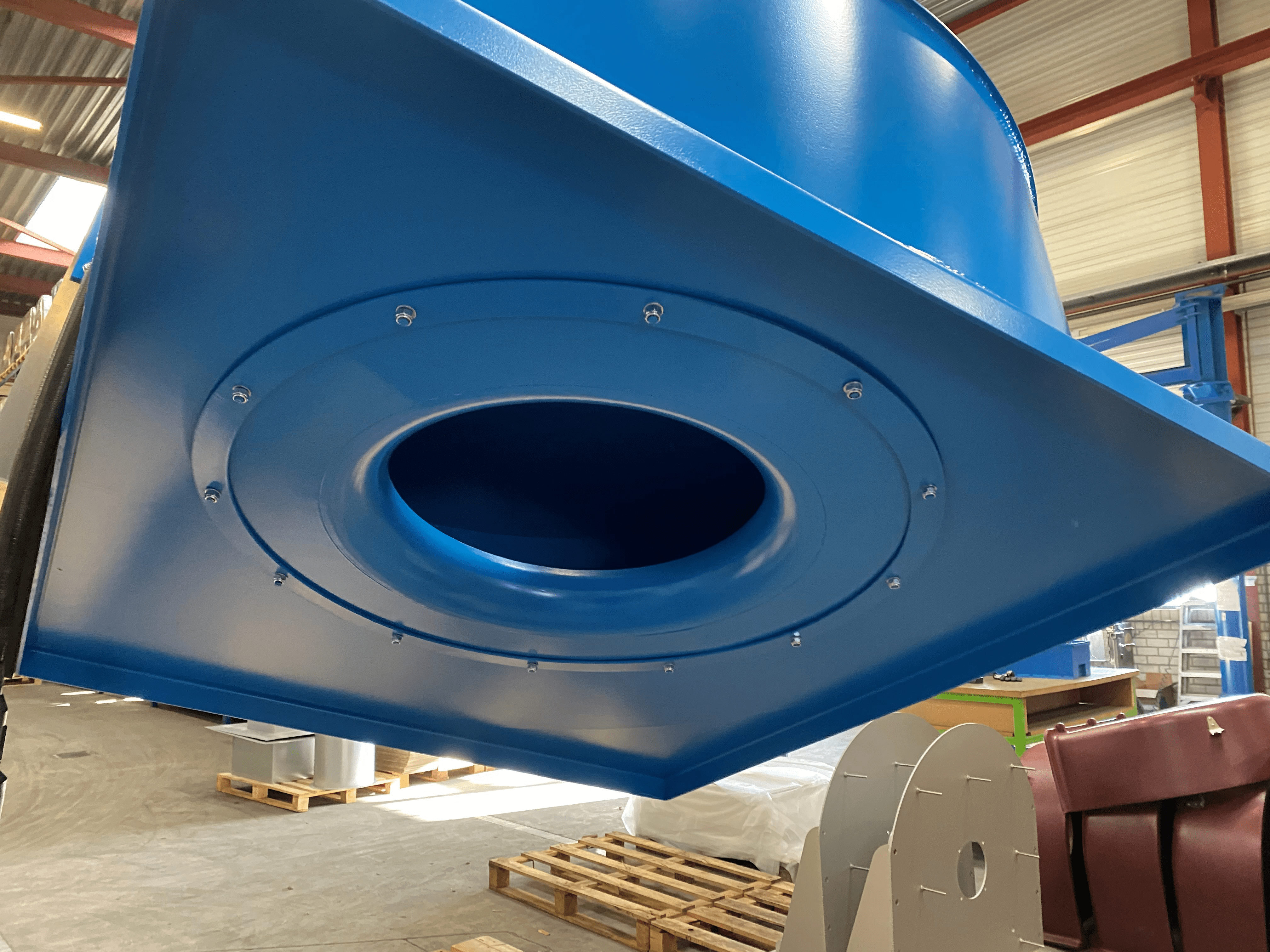

Because of the increasing awareness and extra attention for dust problems, more and more filter builders have emerged in Europe. Because almost all filter builders innovate and want to build as compact as possible, Slingerland Techniek has come up with a solution for a horizontal version that can be mounted directly in the clean air space of the filter cabinet.

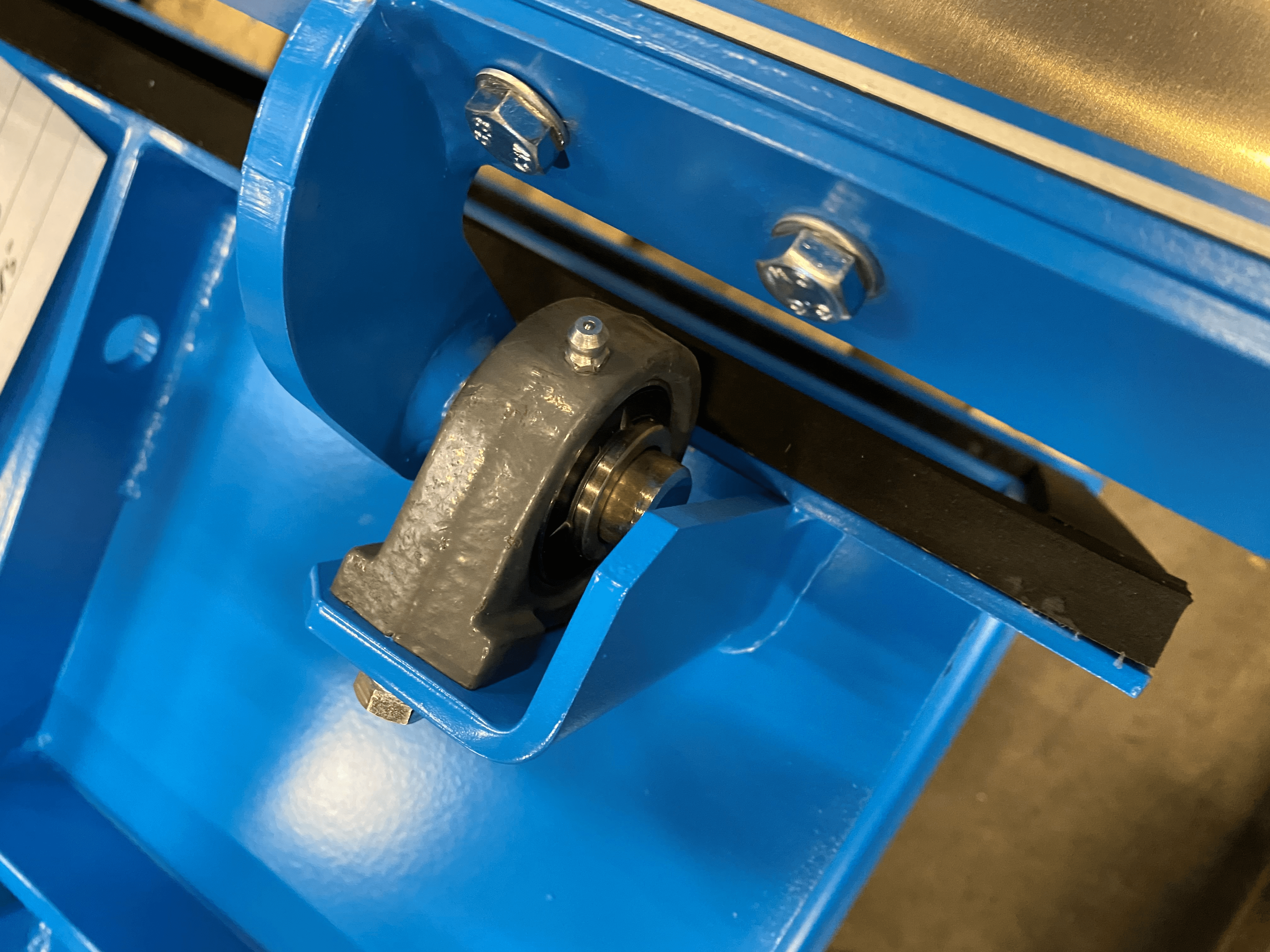

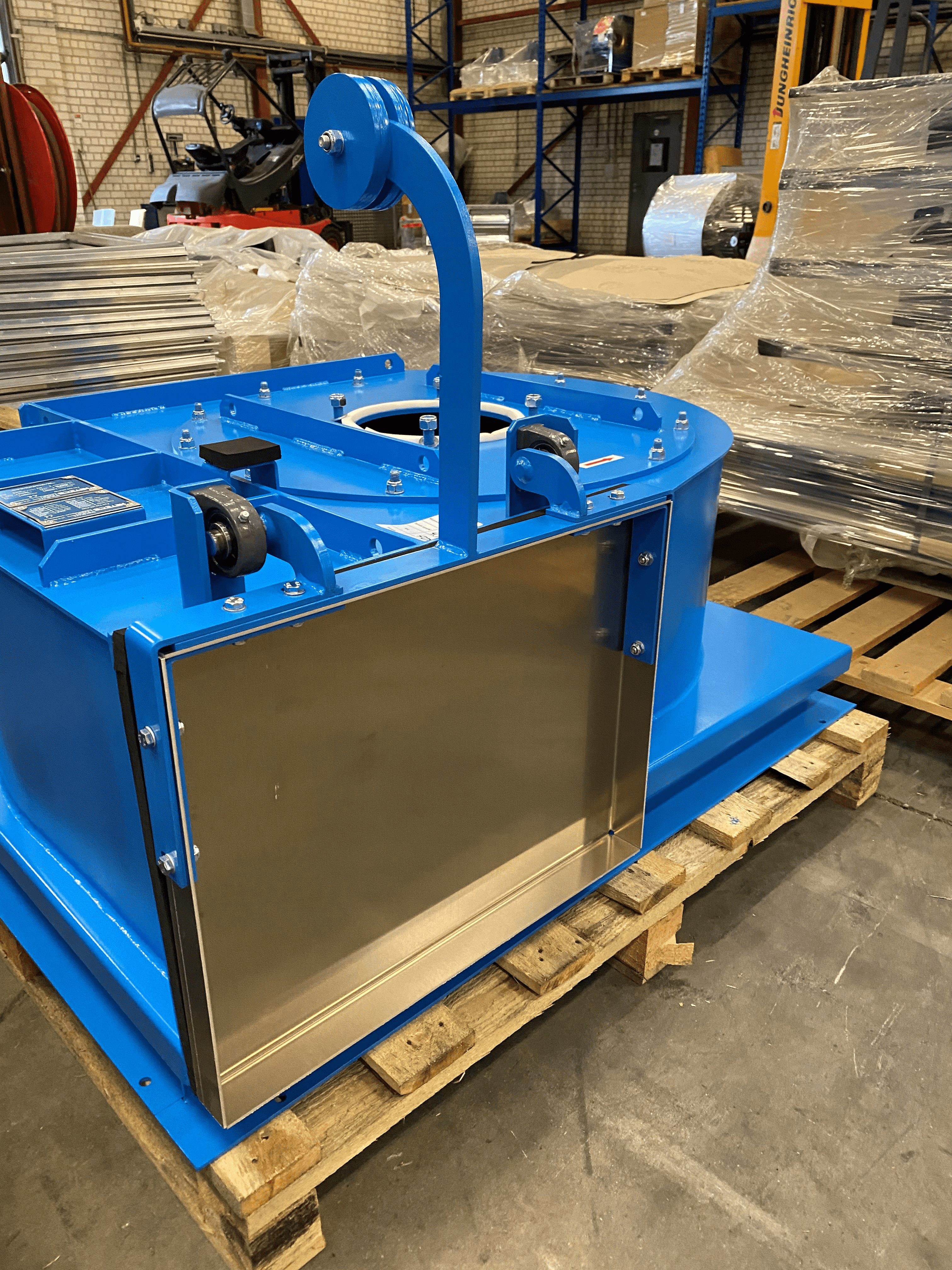

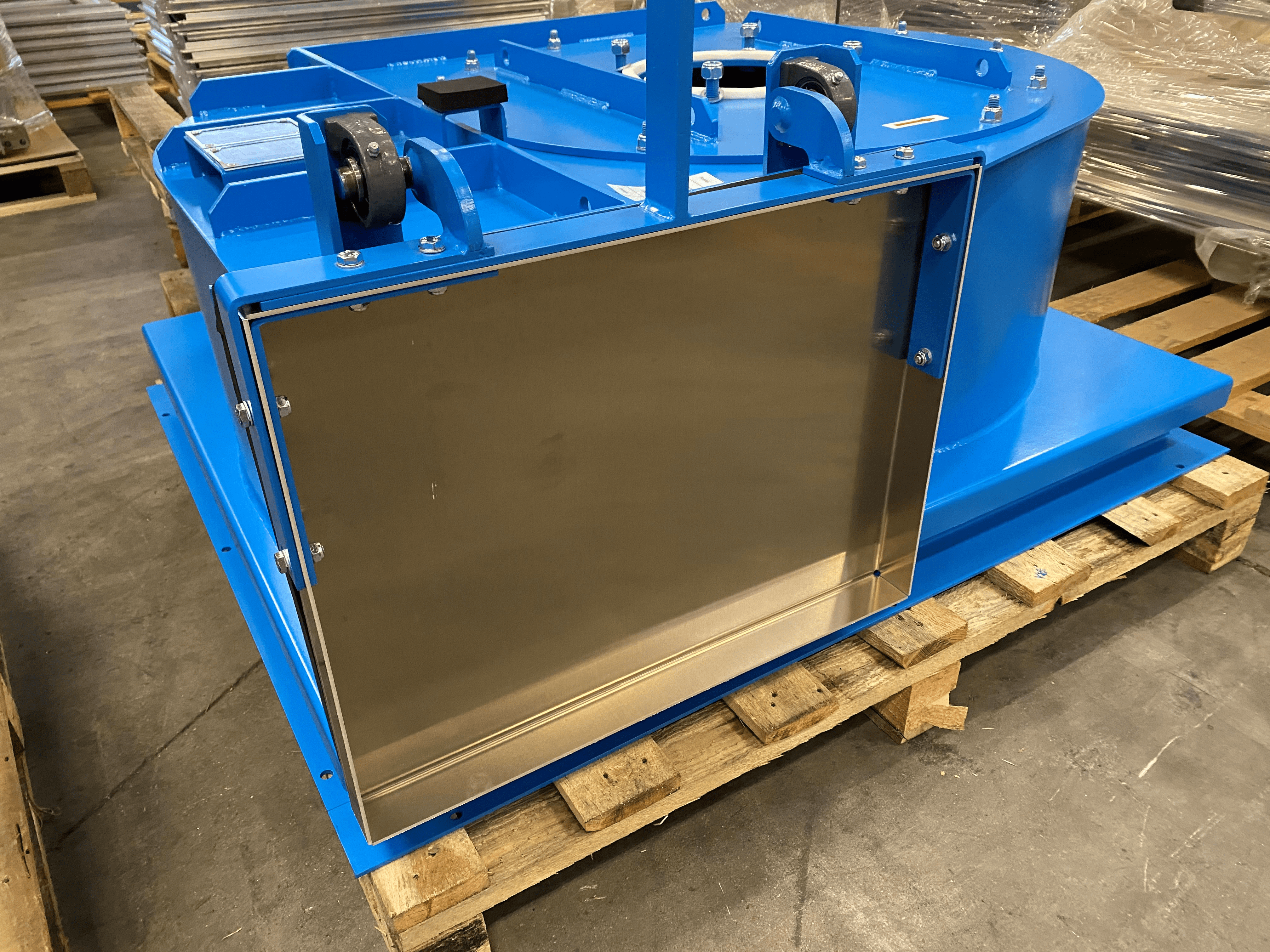

We already provide the fans with a discharge valve with bearing and counterweight. The underframe has been specially developed for easy mounting that is separate from the fan. This is a conscious choice so that first the frame can be easily mounted without the fan getting in the way when mounting. Then the fan can easily be lowered down to the frame. The inlet is completely airtight, making it the only thing that needs to be fitted.

Built-in fans cause significantly less noise nuisance than a separate fan installed next to a filter because the casing of the filter already absorbs a fair amount of noise. If the filter builder provides insulation on top of that on the inside of the filter box, you have a very low-noise system.

In most cases, multiple fans are placed in a filter so that they can be controlled in Cascade. This means that when the installation requires more power, a fan is added. As soon as more suction capacity is needed in the pipes this will be noticed by a pressure sensor. The pressure sensor will then send a signal to the electrical cabinet to switch on an extra fan. In this way a customer can optimally save energy and the installation is easy to assemble. This way, the filter is delivered to the customer ready to use, which simplifies the installation one by one.

You must ensure that each fan has a non-return valve on the outlet. It is important that no air can escape through the fans that are not rotating. This means that when a fan is switched off, the valve on the outlet must close. Slingerland Techniek has come up with some very nice standard solutions for this.

We are happy to help you. Please contact us for free advice on the number +31 (0)33 465 13 92 or go to our contact page below.