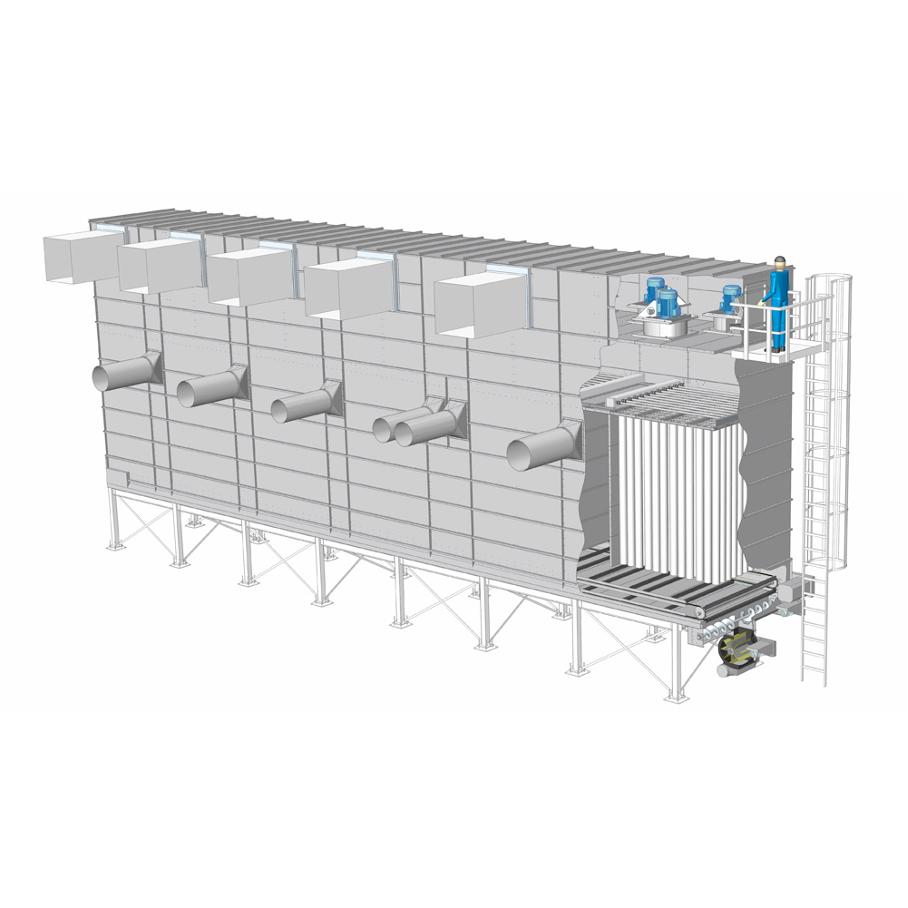

One of our customers, a company specialising in development, construction and maintenance of thermal drying processes received a question from a customer of theirs from the wood industry. Wood chips and sawdust are a source of energy, provided they are sufficiently dried and packaged in a manageable manner. So our client was commissioned to develop a dryer suitable for drying wood chips and fibres sufficiently on a belt dryer. The moisture in the wood chips is reduced so that it can be packed and transported better. This dryer was to be heated using a biofuel-fired furnace.

Input moisture concentration of the material was 55% and output moisture concentration only 12%. The dryer has a capacity of 7500 kg per hour.